Coincidentally, I stumbled upon an impressive case study showcasing how our pressure reducing valves have successfully reduced maintenance costs for numerous industries. In this discussion, I will delve into the importance of pressure reducing valves, share real-life success stories highlighting decreased maintenance costs, and explain how these valves prevent breakdowns. But that’s not all – I will also reveal the significant savings and efficiency that our valves offer, as well as the diverse industries that have already benefited from their implementation. So, let’s explore this intriguing case study together and uncover the potential cost-saving solutions that are waiting for you.

The Importance of Pressure Reducing Valves

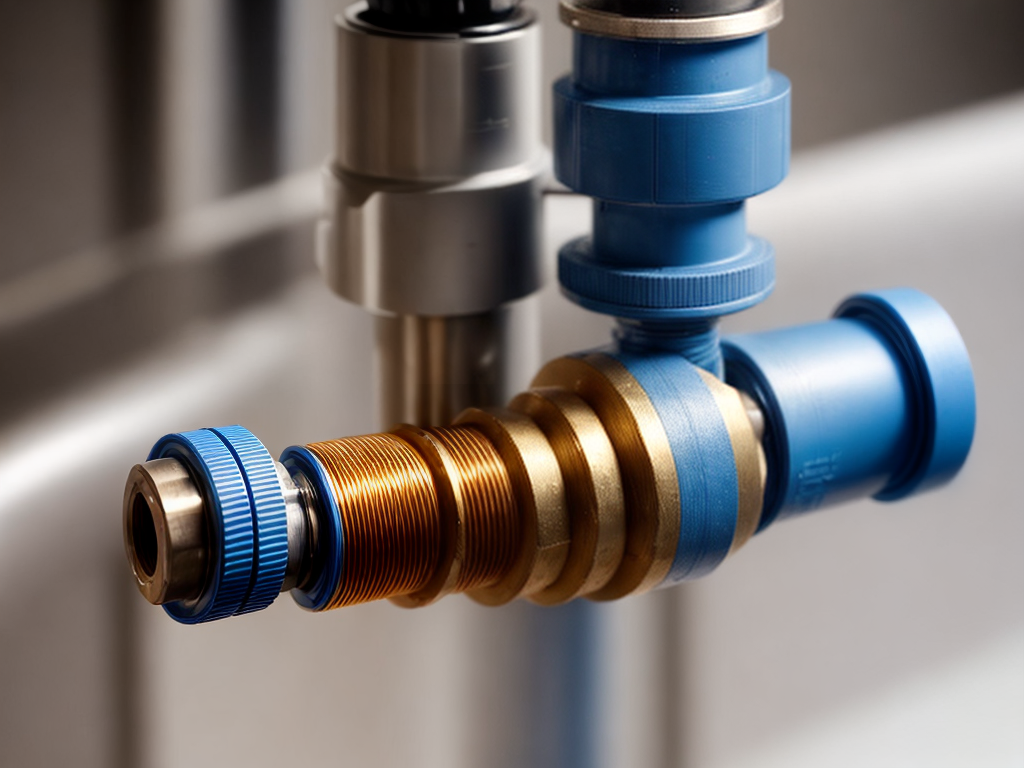

Pressure reducing valves are essential components in any plumbing system, as they play a crucial role in maintaining optimal water pressure levels and preventing potential damage. The importance of pressure reducing valves cannot be overstated, as they provide a reliable solution to regulate and control water pressure in a plumbing system.

The functionality of pressure reducing valves lies in their ability to reduce high water pressure to a safe and manageable level. High water pressure can cause significant damage to pipes, fixtures, and appliances, leading to leaks, bursts, and costly repairs. By installing pressure reducing valves, the risk of such damage is greatly reduced.

These valves work by automatically adjusting the water pressure to a predetermined level, ensuring a consistent and safe flow of water throughout the system. They act as a barrier between the high-pressure supply line and the rest of the plumbing system, preventing excessive pressure from causing harm.

Additionally, pressure reducing valves help to extend the lifespan of plumbing fixtures and appliances by reducing the strain caused by high water pressure. By maintaining a consistent and controlled pressure, these valves minimize wear and tear on the system, resulting in fewer repairs and replacements over time.

Real-Life Success Stories: Decreased Maintenance Costs

By implementing pressure reducing valves, businesses have experienced significant reductions in maintenance costs related to plumbing system repairs and replacements. Here are four real-life success stories that highlight the positive impact of pressure reducing valves on maintenance costs:

-

Reduced Downtime: With pressure reducing valves in place, businesses have reported a significant decrease in system downtime. These valves ensure that the water pressure remains within the optimal range, preventing excessive strain on the plumbing system. As a result, there is less need for emergency repairs and replacements, minimizing downtime and maximizing productivity.

-

Minimized Repairs: Pressure reducing valves help optimize the performance of plumbing systems by regulating water pressure. By maintaining a consistent and controlled pressure, these valves prevent issues such as pipe bursts, leaks, and water hammer. The result is a drastic reduction in the need for repairs, saving businesses both time and money.

-

Extended Lifespan: The use of pressure reducing valves has been shown to extend the lifespan of plumbing systems. By preventing excessive pressure, these valves reduce the wear and tear on pipes, fittings, and other components. This not only decreases the frequency of replacements but also increases the longevity of the entire system, resulting in significant cost savings over time.

-

Improved Efficiency: Pressure reducing valves optimize the performance of plumbing systems by ensuring that water pressure is at the ideal level for each application. This leads to improved efficiency in the use of water, reducing wastage and lowering utility costs. Additionally, by maintaining optimal pressure, these valves help prevent issues such as water hammer, which can cause damage and further increase maintenance expenses.

How Pressure Reducing Valves Prevent Breakdowns

To prevent breakdowns, pressure reducing valves play a crucial role in regulating water pressure within plumbing systems. By maintaining a consistent and safe pressure level, these valves prevent excessive strain on equipment and pipes, ultimately preventing downtime and increasing the lifespan of the entire system.

One of the main reasons pressure reducing valves are effective in preventing breakdowns is their ability to regulate water pressure within a desired range. This ensures that the pressure does not exceed the recommended limits, which can lead to equipment failure or pipe leakage. By controlling the pressure, these valves help to maintain a stable environment for the plumbing system, reducing the risk of sudden breakdowns and costly repairs.

To further illustrate the importance of pressure reducing valves in preventing downtime and increasing equipment lifespan, let’s take a look at the following table:

| Problem | Consequence | Solution |

|---|---|---|

| High water pressure | Equipment damage | Pressure reducing valve |

| Low water pressure | Inadequate performance | Pressure boosting system |

| Pressure fluctuations | Pipe leakage | Pressure stabilizing valve |

As shown in the table, pressure reducing valves address the problem of high water pressure, which can lead to equipment damage. They work alongside pressure boosting systems to ensure that water pressure stays within the optimal range, preventing both excessive strain on equipment and inadequate performance due to low water pressure.

Savings and Efficiency: The Benefits of Our Valves

Our valves offer significant cost savings and increased efficiency for plumbing systems. Here are four reasons why our valves are the cost-effective solution you need for improved performance:

-

Reduced Maintenance Costs: Our pressure reducing valves are designed to prevent overpressure and regulate the flow of water, reducing the strain on your plumbing system. This results in fewer breakdowns and the need for costly repairs or replacements.

-

Energy Efficiency: By maintaining optimal water pressure, our valves ensure that your plumbing system operates at its most efficient level. This not only reduces energy consumption but also extends the lifespan of your equipment, saving you money in the long run.

-

Water Conservation: Our valves help conserve water by preventing leaks and excessive water usage. By regulating the pressure, they minimize the risk of pipe bursts and water wastage, promoting sustainability and reducing your water bills.

-

Improved System Performance: Our valves provide precise control over water pressure, ensuring consistent and reliable performance of your plumbing system. This leads to improved water flow, reduced noise, and enhanced overall system efficiency.

At [Company Name], we understand the importance of cost-effective solutions that deliver improved performance for your plumbing systems. Our pressure reducing valves are engineered with precision and reliability in mind, providing you with the peace of mind that your system is operating efficiently and cost-effectively. Trust us to help you achieve significant savings and improved performance for your plumbing needs.

Industries That Have Benefited From Our Valves

The effectiveness of our pressure reducing valves has been proven across various industries, showcasing their ability to deliver cost savings and improved performance. One industry that has greatly benefited from our valves is the manufacturing sector. In manufacturing, maintaining consistent pressure throughout the production process is crucial for ensuring quality and minimizing downtime. Our pressure reducing valves provide precise control over pressure levels, reducing the risk of equipment failure and production delays. By preventing pressure fluctuations, our valves help manufacturers achieve higher product quality and increased productivity, resulting in significant cost savings.

Another industry that has seen substantial benefits from our valves is the oil and gas industry. In this industry, the safe and efficient transportation of oil and gas is of utmost importance. Our pressure reducing valves play a critical role in maintaining optimal pressure levels in pipelines, preventing leaks, and ensuring the safe transfer of these valuable resources. Additionally, our valves help to reduce energy consumption by optimizing pressure levels, resulting in cost savings for oil and gas companies.